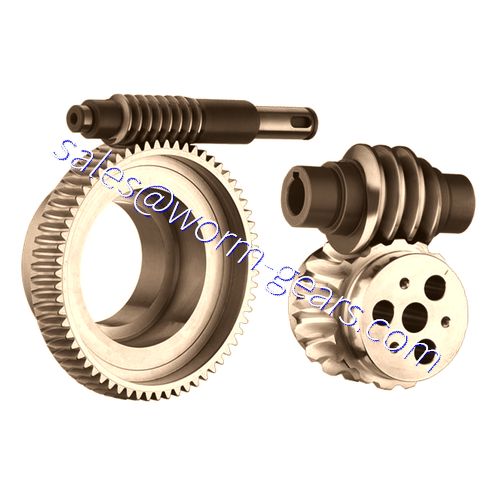

Description

| Legende | ||

| i = gear ratio | da1 = tip diameter (worm) | T2 = output torque |

| γm = Lead angle | z2 = No. of teeth | MF = mineral grease |

| mn = module | dm2 = pitch diameter (worm gear) | MÖ = mineral oil / synthetic grease |

| z1 = number of threads | dA = max. diameter (worm gear) | SÖ = synthetic oil |

| dm1 = pitch diameter (worm) | – | – |

| Axial distance 17 mm | i | Lead angle | mn | Worm | Worm gear | T2 [Nm] | ||||||

| Bronze | ||||||||||||

| CAD-Data | z1 | dm1 | da1 | z2 | dm2 | dA | MF | MÖ | SÖ | |||

| A17U2* | 2.25 | 48° 15′ | 0.9 | 8 | 10.15 | 11.95 | 18 | 23.85 | 25.63 | 1.1 | 1.3 | 1.6 |

| A17U4 | 4.5 | 21° 15′ | 0.75 | 6 | 12.1 | 13.6 | 27 | 21.9 | 24.6 | 1.7 | 2.0 | 2.6 |

| A17U5 | 5 | 21° 37′ | 0.7 | 6 | 11.4 | 12.8 | 30 | 22.9 | 24.6 | 1.8 | 2.2 | 2.7 |

| A17U7 | 7 | 14° 4′ | 1 | 3 | 12.34 | 14.34 | 21 | 21.66 | 24.6 | 1.6 | 1.9 | 2.4 |

| A17U9 | 9 | 9° 40′ | 0.75 | 3 | 13.4 | 14.9 | 27 | 20.6 | 22.7 | 1.5 | 1.8 | 2.2 |

| A17U10 | 10 | 11° 49′ | 0.75 | 3 | 11.0 | 12.5 | 30 | 23.0 | 24.6 | 1.9 | 2.3 | 2.8 |

| A17U15 | 15 | 7° 38′ | 0.75 | 2 | 11.3 | 12.8 | 30 | 22.7 | 24.6 | 1.9 | 2.3 | 2.8 |

| A17U25 | 25 | 4° 32′ | 0.9 | 1 | 11.4 | 13.2 | 25 | 22.6 | 24.6 | 1.8 | 2.2 | 2.7 |

| A17U30 | 30 | 3° 45′ | 0.75 | 1 | 11.45 | 12.95 | 30 | 22.55 | 24.6 | 1.9 | 2.3 | 2.8 |

| A17U40 | 40 | 2° 3′ | 0.5 | 1 | 13.98 | 14.98 | 40 | 20.02 | 21.6 | 1.4 | 1.7 | 2.1 |

| A17U50** | 50 | 3° 12′ | 0.5 | 1 | 8.95 | 9.95 | 50 | 25.05 | 27.2 | 1.0 | 1.2 | 1.5 |

| A17U60 | 60 | 2° 18′ | 0.4 | 1 | 9.95 | 10.75 | 60 | 24.05 | 26.0 | 1.6 | 1.9 | 2.4 |

| A17U75 | 75 | 1° 28′ | 0.3 | 1 | 11.74 | 12.34 | 75 | 22.26 | 24.0 | 1.5 | 1.8 | 2.2 |

| A17U80 | 80 | 1° 43′ | 0.3 | 1 | 10.0 | 10.84 | 80 | 24 | 25.1 | 1.5 | 1.8 | 2.2 |

* Worm gear set A17Ü2 is available only with a polished (smoothed) worm profile and helical-toothed gear.

** The worm of worm gear set A17Ü50 has a hub diameter of 9 mm.

Steel, right-hand threaded worm, case hardened HV 620 – 700.

Worm gear made of CuZn37Mn3Al2PbSi or plastic or laminate 2083 upon request.

The output torque rating (T2) applies to the initial speed of 2800 rpm at the worm (shaft).

The efficiency values (see table in worm gear set catalog) are guidelines. The bearing, lubrication, speed, and installation, in addition to the lead angle, can influence efficiency.

Gears may be combined only with worms of the same axial distance and with the same transmission ratio.

Worms or worm gears from other manufacturers may not be paired with the counterpiece. It is almost always necessary to adjust the toothing specifications.

All dimensions can be adapted upon request.

As one of the leading worm gear manufacturers, mechanical product suppliers and exporters, we supply worm gear and many other products for cluster worm gear. worm gear, worm gear Manufacturer, worm gear Supplier, worm gear Exporter, worm gear Seller, worm gear Made In China, Wholesale worm gear, Buy worm gear, Customize worm gear- Find worm gear Manufacturers and Suppliers. Choose from quality worm gear manufacturers, suppliers and exporters on worm-gears.com.